Electroplating Deposition Rate . In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. The latter parameter plays an important. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal.

from www.mdpi.com

The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. The latter parameter plays an important. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs.

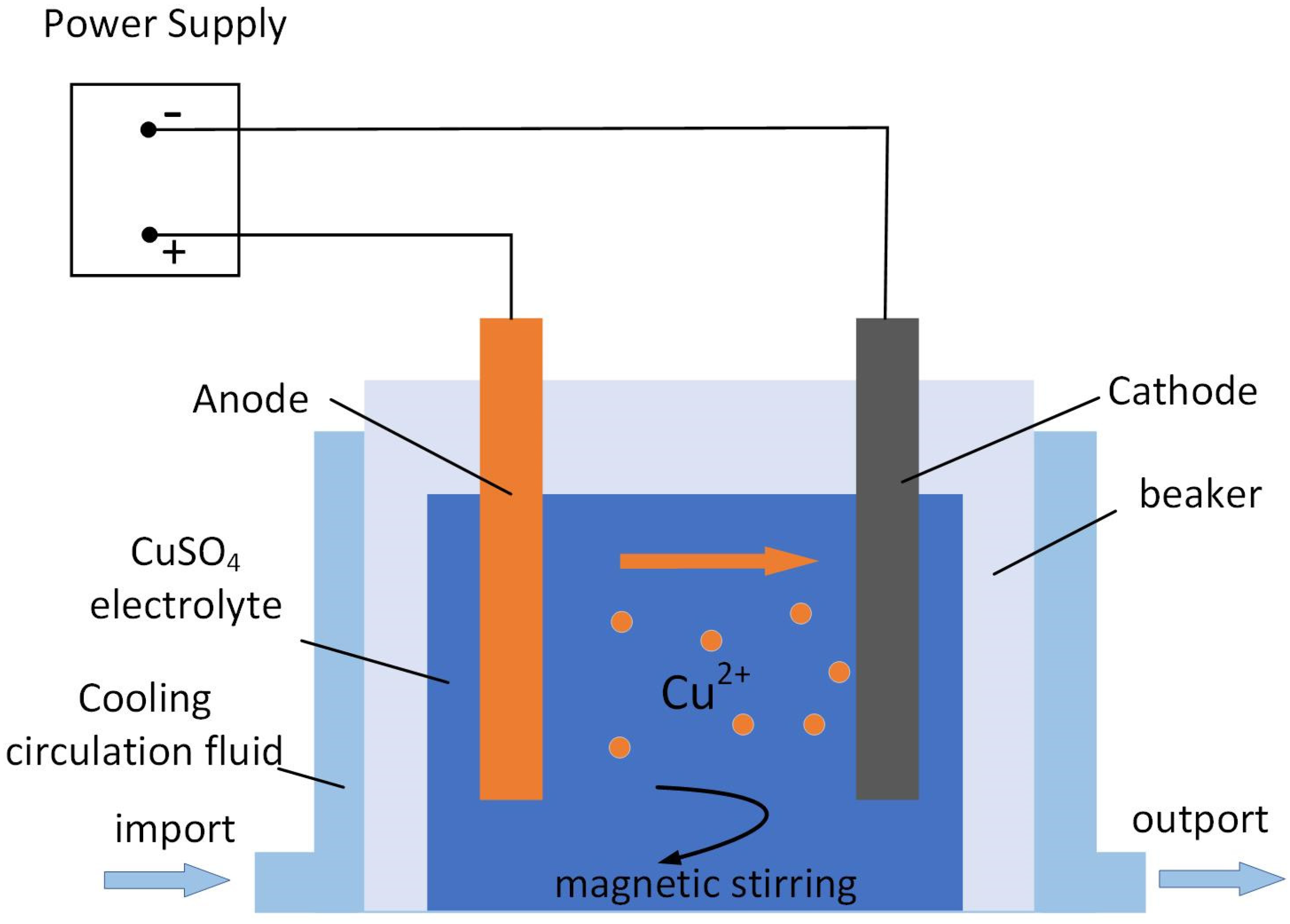

Micromachines Free FullText Study of Copper Electrodeposition at a

Electroplating Deposition Rate The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The latter parameter plays an important.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The latter parameter plays an important. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. For advanced. Electroplating Deposition Rate.

From www.mdpi.com

Metals Free FullText An Improved Optimization Model to Predict the Electroplating Deposition Rate The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The latter parameter plays an. Electroplating Deposition Rate.

From www.mdpi.com

Metals Free FullText An Improved Optimization Model to Predict the Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. For advanced packaging applications, it is important to. Electroplating Deposition Rate.

From comsol.fr

Electrodeposition Software Controlling Electrodeposition Processes Electroplating Deposition Rate The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. The latter parameter plays an important. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have. Electroplating Deposition Rate.

From pubs.acs.org

Deposition and Stripping Behavior of Lithium Metal in Electrochemical Electroplating Deposition Rate This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The latter parameter plays an important. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location.. Electroplating Deposition Rate.

From www.researchgate.net

Does agitation effect the deposition rate in Electrodeposition of Electroplating Deposition Rate For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The key to. Electroplating Deposition Rate.

From graduateway.com

The Effect of Surface Area on the Rate of Electrodeposition in Electroplating Deposition Rate The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The deposition rate during the electroplating process significantly. Electroplating Deposition Rate.

From www.comsol.it

Modeling Copper Electrodeposition on a Circuit Board COMSOL Blog Electroplating Deposition Rate The latter parameter plays an important. In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings.. Electroplating Deposition Rate.

From mavink.com

Electroplating Process Flow Chart Electroplating Deposition Rate The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. In electroplating, higher temperatures can increase the deposition rate as. Electroplating Deposition Rate.

From www.researchgate.net

Average grain size obtained from SEM images (a) and the deposition rate Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The rate of deposition of the. Electroplating Deposition Rate.

From www.researchgate.net

b. Copper deposition is more uniform when low current density is used Electroplating Deposition Rate The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. For advanced packaging applications, it. Electroplating Deposition Rate.

From www.comsol.fr

Electroplating How the U.S. Mint Makes a Penny COMSOL Blog Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. The latter parameter plays an. Electroplating Deposition Rate.

From www.researchgate.net

2D phasefield simulation of Li deposition on 3D PPSCu and bare Cu Electroplating Deposition Rate The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. For advanced packaging applications, it is important to carefully control the copper plating rate and deposition location. The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. The latter parameter plays an. Electroplating Deposition Rate.

From knowledge.electrochem.org

Electrochemistry Encyclopedia Atomic layer deposition Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The key to successful electroplating. Electroplating Deposition Rate.

From www.youtube.com

Electroplating process/Electrodeposition Corrosion Control YouTube Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. For advanced packaging applications, it is important. Electroplating Deposition Rate.

From www.mdpi.com

Metals Free FullText An Improved Optimization Model to Predict the Electroplating Deposition Rate In electroplating, higher temperatures can increase the deposition rate as the ions in the solution have more energy to overcome. The latter parameter plays an important. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. The deposition rate during the electroplating process significantly influences the uniformity and overall quality of the final metal. This. Electroplating Deposition Rate.

From www.intechopen.com

Parametric Variables in Electrodeposition of Composite Coatings Electroplating Deposition Rate The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. The deposition rate during the electroplating process significantly. Electroplating Deposition Rate.

From ietresearch.onlinelibrary.wiley.com

Development of seed layer deposition and fast copper electroplating Electroplating Deposition Rate The rate of deposition of the metal layer depends on the temperature and gas pressure at which the process occurs. The latter parameter plays an important. The key to successful electroplating is controlling parameters such as the electrolyte solution’s current density,. This paper provides a general survey of research on the electrodeposition of ni p binary alloy coatings. The deposition. Electroplating Deposition Rate.